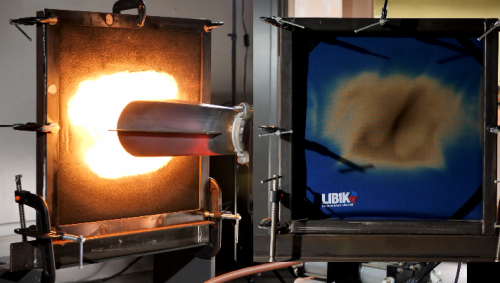

LIBIK fabrics being subjected to a 30 minute Powerplant Test at Aeroblaze Lab

Companies depend on the LIBIK line of products to extinguish lithium-ion battery fires and keep the fire fighter safe. So Dylan Vandemark, VP of Product Development at CellBlock FCS, tests above industry standards to ensure the products will perform in an emergency situation.

To-date CellBlock’s textiles have passed a 12-second vertical flame test, a 60-second vertical flame test, and a 30-minute oil burner test. Last week CellBlock completed experimental testing at Aeroblaze Laboratory on the LIBIK fabrics. It was a variation of FAA 14 CFR 25.1193(d), Advisory Circular No. 20-135, DOT/FAA/AR-00/12, Chapter 12 – a powerplant test that runs in excess of 1093 degrees celsius (2000 degrees Fahrenheit). This test is extreme. The powerplant test is not typically performed on textiles. At 5 minutes with no burn-through materials are considered fire resistant; at 15 minutes they earn a fireproof rating. At CellBlock’s request, the lab completed 30 minutes of testing during which there was no indication of burn-through. Performing this procedure on textiles is unheard of. These textiles are simply incredible.

We believe in testing our materials beyond what is required. Our fire suppression kits contain CellBlockEX, a unique and powerful dry extinguisher that works very rapidly to mitigate the event. So there is minimal chance the LIBIK suppression/containment bag would ever be exposed to extended periods of high heat from a thermal runaway. However, our Fire Shield Blanket also relies on these extremely robust fabrics, and is integral to our kits. Protecting the crew member/firefighter is a priority. The blanket effectively provides an impervious barrier between them and the battery fire.

No thermal runaway event is ever the same. Lithium-ion battery fires burn very hot and are nearly impossible to extinguish by traditional means. The integrity of the fabrics in our suppression kits and fire retardant blankets is crucial, which is why we use some of the best materials in the world.